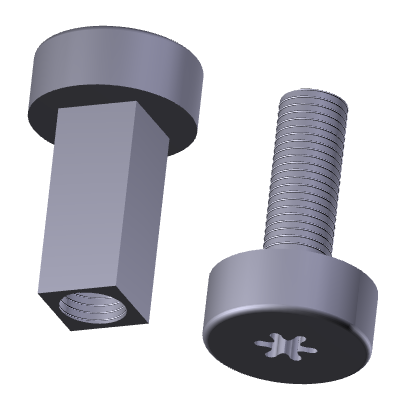

As you might be able to see from the second photo, these pieces required using multiple planes to stack all the parts together, especially the little indent where the screwdriver goes in. Another feature that was a first-time-use for me was a spiraled extrusion, which I used to put the grooves onto the main body of the screw. Here are some better photos of the final first version:

I showed this to peter, and, while the general idea was correct, he wanted me to try and make the base with slanted edges and the body a little skinnier. The reason for the slanted edges of the base is that we wanted it to be as flat as possible against the surface of the handle, so the screw would actually be screwed deep enough that the base would rest within the handle and the surface would be completely level. Here's a look at version two:

I made this version into a SolidWorks drawing to show the dimensions to Peter and he made some corrections on that.

From this version you can see that he wanted to try a version where the "outer" screw featured a rectangular body instead of cylindrical. We also went back to the original width for this one because of the extra space needed to fit the rectangular shape on the base with a cylindrical hole on the inside. Take a look:

I decided to show a picture of this version with the two pieces fitted together, that way it might give a clearer picture of the final idea. The suitcase handle would be in the middle and you would see the two ends on either side. However, we still wanted it skinnier and Peter had a few other modifications. Here's a look at his third round of corrections:

So I made a fourth version, trying to get the body a thin as possible without being unrealistic about the durability of the metal. I also rounded out the edges of the base for a more polished look, forgoing the embedded base with slanted edges.

This ended up being the final version I gave to Peter. And as you can see, even for something as small as a screw on a handle, it took four different versions to get the right look, reinforcing the idea that every detail matters. I think that paying attention to every detail requires having a preference for every detail, and that requires a strong brand identity. Tumi's brand identity is strong in every way: it shows by what they hang on their walls, the way they present their merchandise and the way the team is managed. I'm so grateful that now I have such a high standard of comparison. Up next is a project I'm really proud of: accent kit zipper pulls!

No comments:

Post a Comment